Appendix E

Calculation Methods AppendixPart II.C.3.b

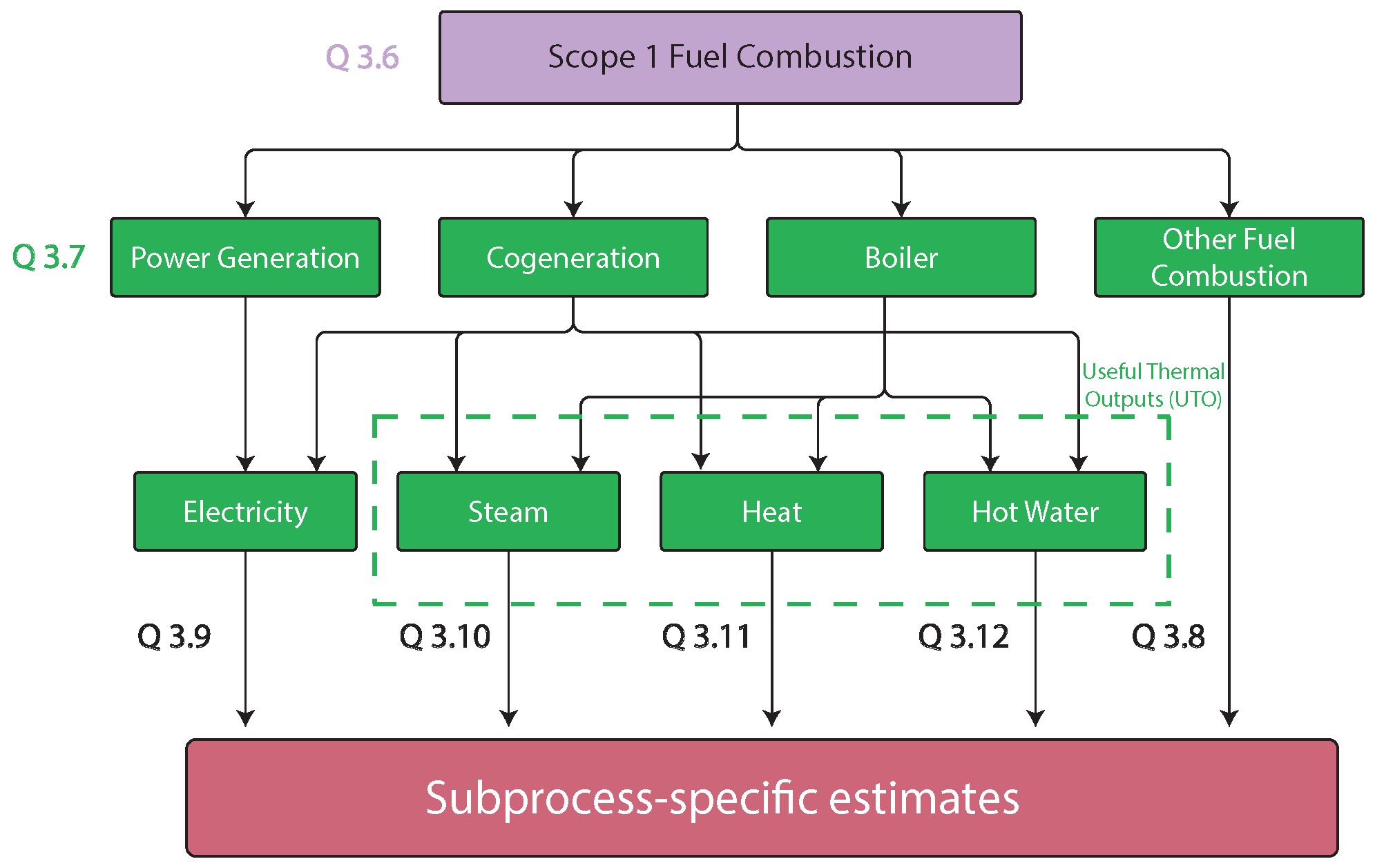

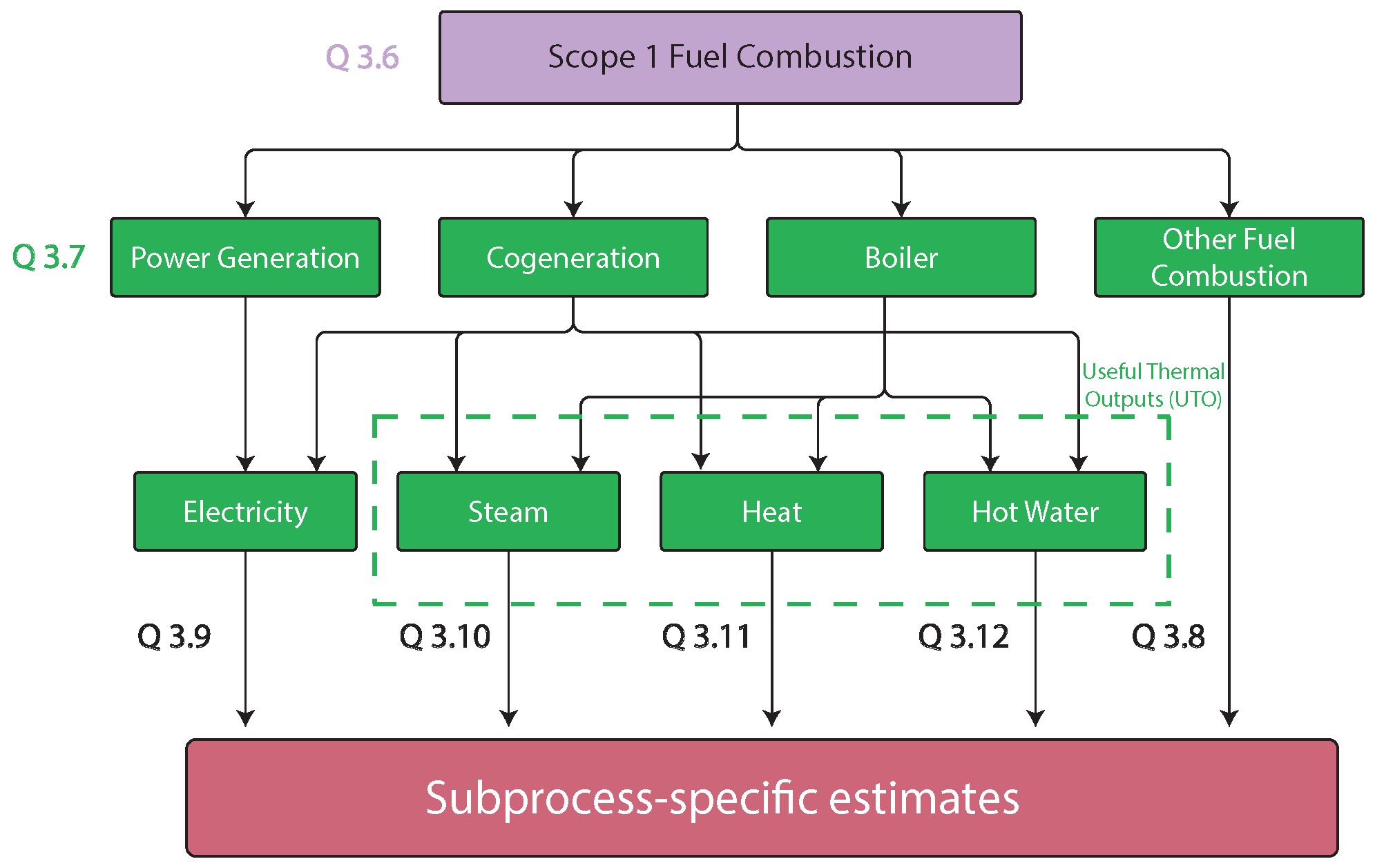

II.C.3.b Fuel Combustion Emissions for Facilities with On-Site Generation

or Boiler Units

Some facilities use on-site fuel combustion to run power

generation, cogeneration, or boiler units, and then use the resulting

electricity, steam, heat, and hot water in various subprocesses. These

facilities may also source additional energy from off-site, particularly for

electricity. Within the facility, however, there is no difference between

consuming the portion of energy sourced from on-site units and consuming the

portion of energy purchased from a third party.532F

For this reason, the calculations assume that the proportional use of each

energy type is the same across all sourcese.g., that

electricity from an on-site unit and electricity sourced from the grid was used

in the same proportions as the facility-wide data in question 3.9 for each

subprocess. The questionnaire required facilities that reported the use of

on-site power generation, cogeneration, or multipurpose nonelectric boiler

units to first allocate fuel use among these units and all other on-site fuel

combustion in question 3.7. For these facilities, the subprocess-specific

quantities of fuel use reported in question 3.8 only represented fuel that was

not first combusted in the generation or boiler units, to avoid double

counting. The calculations instead used data in questions 3.9 through 3.12 on

subprocess-specific use of electricity, steam, heat, and hot water to allocate

the emissions from the power generation, cogeneration, and boilers to

subprocesses. This mapping of fuel combustion in power generation,

cogeneration, boiler units, and all other fuel combustion to electricity,

steam, heat, hot water, and question 3.8 fuel use to develop

subprocess-specific emission estimates is shown in figure E.1, below.

Figure

E.1

Mapping of facility-wide scope 1 fuel combustion emissions to

subprocess-specific estimates

Source: Compiled by the USITC.

Note: The “Q” labels in the diagram

above indicates the question number in the Commission’s facility-level

questionnaire gathering this information. USITC, Greenhouse Gas (GHG)

Emissions Intensities Questionnaire: Facility-Level, 2024, section 3.

Calculating the subprocess-specific emissions for other fuel

combustion (from question 3.7) is similar to the subprocess-specific fuel

combustion calculation for facilities with less complicated energy sourcing.

The only difference is that the facility-wide emissions are multiplied by an

additional ratio to remove the fuel-specific emissions associated with

generation and boiler units (equation E.16). This ratio is the amount of fuel

used in all other on-site fuel combustion in question 3.7 ( ) divided by the total fuel use reported in

question 3.7 ( ).

|

|

|

|

As shown in figure E.1, fuel combustion quantities from

question 3.7 ( ,

,

) determine the share of the facility-wide,

fuel-specific emissions to apply to the facility’s power generation,

cogeneration, and boiler units, respectively. Cogeneration units produce a mix

of electricity and useful thermal outputs (steam, heat, and hot water), and

boilers may produce more than one type of useful thermal output. Equations E.17E.19 first

compute the fuel combustion emissions for each of these units ( ,

,

), before further allocating the unit

emissions to their different energy outputs.

|

|

|

|

|

|

|

|

|

|

|

|

The fuel-specific emissions for each unit are then totaled

across fuel types to estimate total fuel combustion emissions for each unit.

The formula for power generation units is shown as an example in equation E.20.

|

|

|

|

Before estimating subprocess-specific scope 1 emissions from

electricity use, the calculations split apart emissions from cogeneration units

between electricity and useful thermal outputs .

The DOE’s identification number for the facility’s cogeneration units, as reported

in question 3.3c, is used to identify the unit’s electric allocation factor ( ) in eGRID’s plant-level data.533F

Equation E.21 uses this factor to estimate the share of the cogeneration unit’s

emissions associated with the unit’s electric power output ( ).

|

|

|

|

For any facilities generating more electricity than they

used at the facility, the questionnaire allowed a negative value to be reported

in question 4.1 for electricity purchases. Equations E.22.a and E.22.b

calculate scope 1 fuel combustion emissions associated with electricity for

facilities with negative net purchases and positive net purchases,

respectively. Equation E.22.a incorporates the ratio of electricity used

on-site, where represents negative net purchases (electricity

sold off-site) and ( ) is the sum of on-site electricity generation

reported in question 3.3.

Else:

Then, equation E.23 allocates facility-wide scope 1

electricity generation emissions ) to subprocesses .

|

|

|

|

The next set of equations split emissions from non-electric

cogeneration ( and boiler units to develop emissions estimates for steam,

heat, and hot water use. Non-electric cogeneration emissions are the total

emissions associated with on-site generation of useful thermal outputs

(equations E.24 and E.25):

|

|

|

|

|

|

|

|

First, if a facility reported net sales of these outputs ( ,

equations E.26.a and E.27.a applied a ratio of thermal outputs used on-site ( ) to outputs generated on-site ( ).534F

This ratio removes the emissions associated with thermal outputs that were sold

from the facility and used instead by third parties. When a facility sells more

thermal output than it purchases, no scope 2 emissions are estimated for the

quantity of purchased output; the quantity purchased is instead treated as if it

were sourced from the facility’s on-site generation of that thermal output.

This is consistent with how electricity was treated (using data on net

electricity purchases) and with GHG Protocol guidance.535F

In addition to adjusting for any net sales of thermal outputs, equations E.26

and E.27 proportionally break out emissions for cogeneration and boiler units

based on the relative quantities of each type of thermal output produced from

each unit (e.g., ( ). Equations E.26 and E.27 are calculated for

each of the types of useful thermal output (steam, heat, and hot water).

Equation E.28 combines the emissions for each useful thermal output from

cogeneration units with the emissions for that output from boiler units.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Equation E.29 then allocates the estimates for scope 1 fuel

combustion associated with the facility’s generation of steam, heat, and hot

water at on-site units ( ) to each of the subprocesses. The allocations

for steam, heat, and hot water were reported directly in questions 3.103.12 as

estimated percentage shares ( ).536F

|

|

|

|

Finally, equation E.30 totals the subprocess-specific

estimates for scope 1 fuel combustion emissions ) from scope 1 electricity, steam, heat, hot

water, and other fuel combustion. For fuel combustion not used in power

generation, cogeneration, or boiler units, the subprocess-specific emissions

are first totaled across all fuel types ( ).

|

|

|

|

From this point in the calculations, the allocation of any

emissions from ambient heating and the aggregation of subprocesses to unit

process emissions for scope 1 fuel combustion follow the same steps as with

simpler facilities (equations E.11E.13).

These final steps yield scope 1 fuel combustion unit process emissions ( for the product-level emissions inventories.