Appendix E

Calculation Methods AppendixPart III

III. Computing Product-Level Emissions

Inventories

After the Commission has allocated the emissions data from

facilities to subprocesses and unit processes as described above, it takes the following

steps to prepare product-level emissions inventories. As shown in equation E.2

above, the product-level emissions inventory of each reference product ( ) includes two main components: (1) unit

process emissions encompassing all direct emissions that occur during the unit

process as well as indirect emissions from energy and externally sourced

materials used in that unit process ( ); and (2) the sum of all emissions associated

with upstream materials made in the same facility and used in the production of

the reference product ( ). The sections above describe the methods for

calculating each scope’s contribution to unit process emissions, which are

summed to equal in equation E.3. This section describes the

Commission’s calculation of and its incorporation of this term into using material flow analysis.

is

a portion of the facility’s product-level emissions inventory for its own on-site

production of an upstream product used as a material ( ) in the production of the reference product (

). The Commission calculated using equation E.60.

|

|

|

|

Equation E.60 is the product of:

·

:

the facility’s product-level emissions inventory for .

·

:

the “internal consumption share” for ,

or the share of the facility’s output of that is used in on-site production as opposed

to shipped off-site. Equation E.60’s incorporation of the internal consumption

share ensures that downstream product-level emissions inventories do not

include emissions associated with quantities of that are shipped off-site.

·

:

the facility’s use of from all sources (including external receipts

and on-site production) in the production of as a share of the facility’s total use of .

The material use data are from questionnaire data in which

facilities reported their use of materials in specific subprocesses ( ). Where a subprocess produces multiple

reference products, material use data at the subprocess level ( ) are split using a similar physical

allocation approach to that used above to allocate facility-level emissions to

unit processes (see equation E.61).

|

|

|

|

In effect, this approach uses emissions inventories for

upstream products made at facilities for multiple purposes.567F

Because the upstream products made at a facility have a portion of their

emissions inventories included within those of further downstream products, the

term must be calculated sequentially starting with

the furthest upstream reference products. This ordered approach is referred to

in this report as “material flow analysis” and is based on a combination of

Commission research into how unit processes relate to each other in steel and

aluminum facilities as well as the information provided in questionnaire

responses in which facilities identified how they used materials.

III.A. Material Flow Analysis for the Steel System

Boundary

For reference products in the steel system boundary,

material flow analysis begins with calculation of for industrial gas products: oxygen, nitrogen,

argon, and hydrogen. Industrial gas products are assumed not to use other

products made at steel facilities as materials and are also potentially used to

make most of the downstream reference products. Therefore, for these products

(which are rarely made at steel facilities), = without the inclusion of any derivative of .

Subsequent calculations of become more complex as they include additional

derivatives of .

Table E.11 provides a list of all reference products ( ) for which values of were calculated, ordered by the sequence in

which these values were calculated. For each ,

a list of materials ( ) includes all upstream products that wereor

potentially could beproduced

by facilities and that could be used as materials in the production of .

Each and combination listed in table E.11 has a

corresponding term for that is included in the calculation of .568F

If a facility does not have production of or does not use in the production of the ,

then corresponding with will not contribute any emissions to .

Table E.11 List of materials made at

steel facilities that are used in the production of reference products

(em dash) = not applicable.

|

Reference products made at steel facilities

(in calculation order)

|

Corresponding materials made on-site at steel

facilities that could be used to produce the reference product

|

|

Oxygen

|

|

|

Nitrogen

|

|

|

Argon

|

|

|

Metallurgical coke

|

Oxygen, Nitrogen

|

|

Calcined lime

|

Oxygen, Nitrogen

|

|

Calcined dolime

|

Oxygen, Nitrogen

|

|

Iron sinter

|

Metallurgical coke, Calcined lime, Calcined

dolime, Oxygen, Nitrogen

|

|

Pig iron

|

Iron sinter, Metallurgical

coke, Calcined lime, Calcined dolime, Oxygen, Nitrogen

|

|

Semifinished steel products

|

Pig iron, Metallurgical coke, Calcined lime,

Calcined dolime, Oxygen, Nitrogen, Hydrogen, Argon

|

|

Hot-rolled flat steel

products

|

Semifinished steel products,

Oxygen, Nitrogen, Hydrogen

|

|

Cold-rolled flat steel products

|

Hot-rolled flat steel products, Oxygen,

Nitrogen, Hydrogen

|

|

Coated flat steel products

|

Hot-rolled flat steel

products (if not cold rolled before being coated), Cold-rolled flat steel

products, Oxygen, Nitrogen, Hydrogen, Argon

|

|

Hot-worked long steel products

|

Semifinished steel products, Oxygen, Nitrogen,

Hydrogen

|

|

Cold-formed long steel

products

|

Hot-worked long steel

products, Oxygen, Nitrogen, Hydrogen, Argon

|

|

Seamless tubular steel products

|

Semifinished steel products, Hot-worked long

steel products, Oxygen, Nitrogen, Hydrogen, Argon

|

|

Non-seamless tubular steel

products

|

Hot-rolled flat steel

products, Cold-rolled flat steel products, Coated flat steel products,

Hot-worked long steel products, Oxygen, Nitrogen, Hydrogen, Argon

|

Source: USITC, Greenhouse Gas

(GHG) Emissions Intensities Questionnaire: Facility-Level, 2024, responses

to questions 2.1.1, 5.1.6a, 5.1.8a, 5.1.9a, 5.1.10a, 5.1.10b, 5.1.10c, 5.1.13a,

5.1.17a, 5.1.18a, 5.1.19a, 5.1.20a, 5.1.23a.

Note: Where the upstream material is

itself a steel product, only the emissions associated with that type of steel

were included in the inventory. For example, if a facility produced both

stainless steel and carbon and alloy steel types of semifinished steel and used

those products to make both types of hot-worked long steel products, then only

the emissions associated with the facility’s production of stainless

semifinished steel would be used within the emissions inventory for production

of stainless hot-rolled flat steel products (and vice versa for carbon and

alloy products).

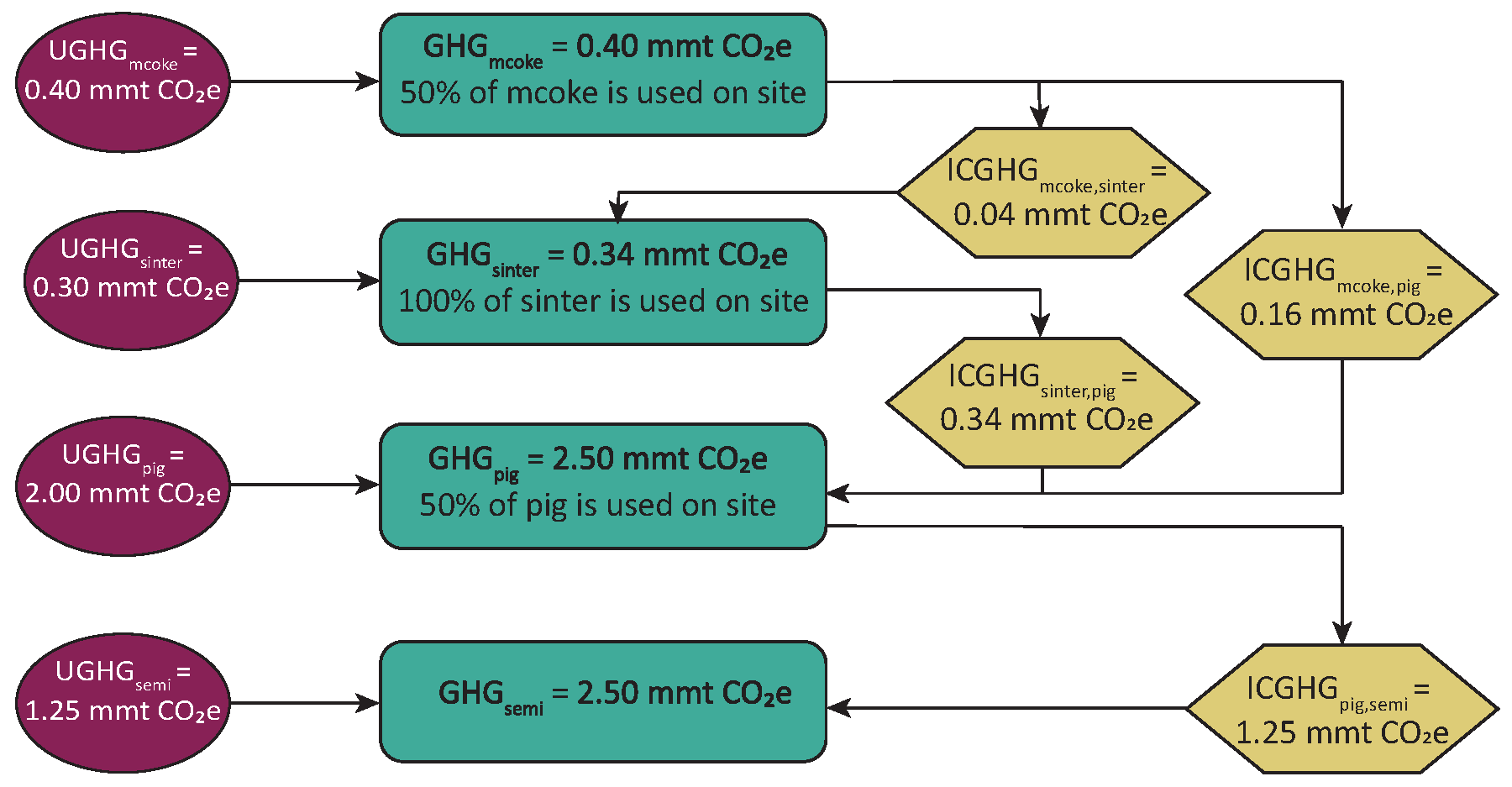

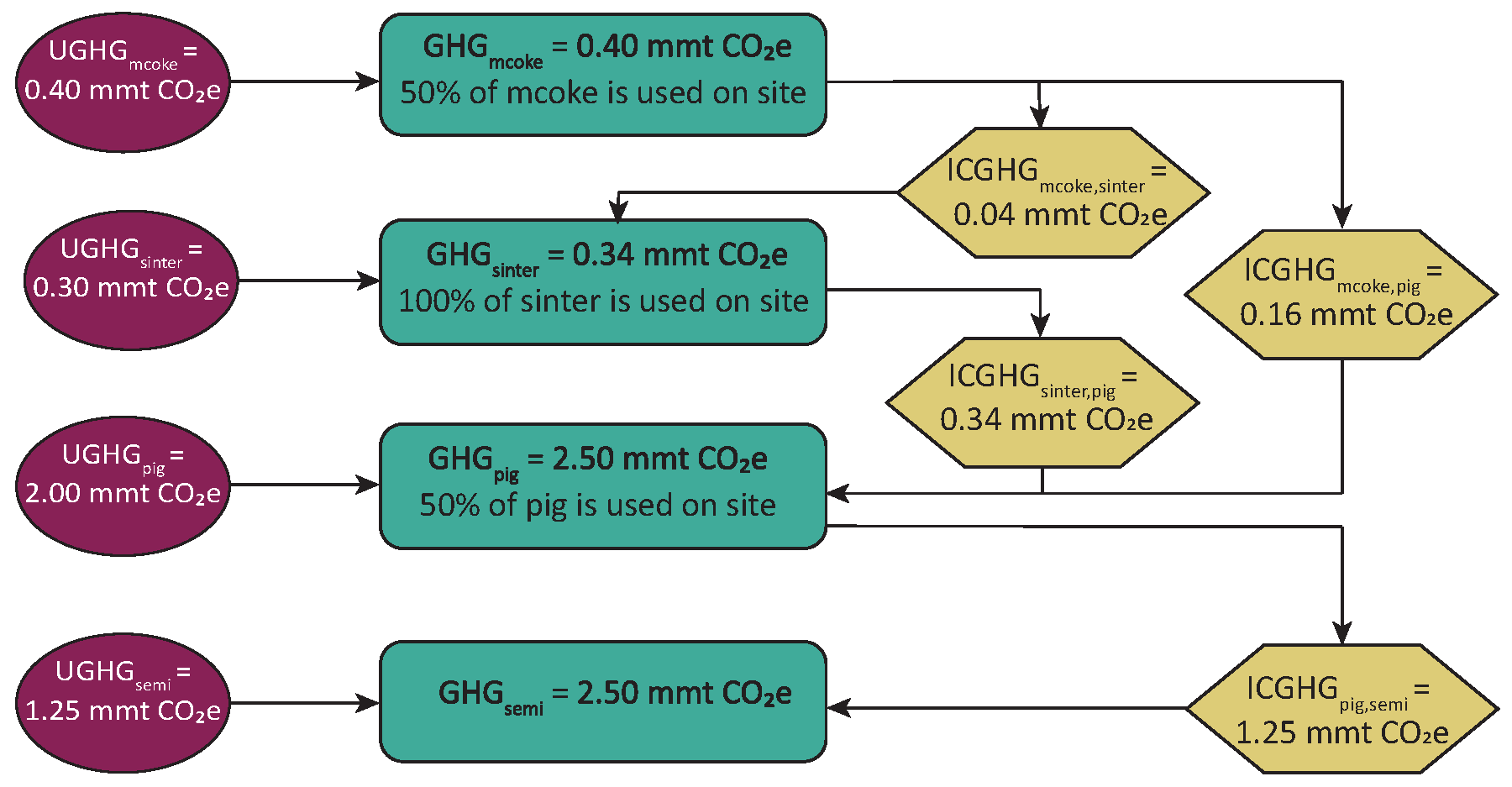

An example of how is calculated is illustrated by the production

of carbon and alloy semifinished steel in a hypothetical integrated steel

facility (see figure E.4). In this example, the facility produces the following

reference products and associated unit process emissions:

·

1.00 million metric tons (mmt) of metallurgical

coke associated with unit process emissions ( of 0.40 mmt CO2e. Of this

production, 0.50 mmt (50 percent) of this material is used on-site to produce

other products. The facility reports that 80 percent of the metallurgical coke

that it uses is used in blast furnace operations and 20 percent is used in iron

sinter production.

·

1.00 mmt of semifinished steel in BOF

steelmaking associated with unit process emissions ( ) of 0.40 mmt CO2e.

·

1.20 mmt of pig iron associated with unit

process emissions ( of 1.80 mmt CO2e. Of this

production, 0.90 mmt (75 percent) is used on-site to produce other products and

0.30 mmt is shipped to other facilities. The facility reports that all of the

pig iron that it uses is used in blast furnace operations (production of pig

iron).

·

1.40 mmt of iron sinter associated with unit

process emissions ( of 0.30 mmt CO2e. All iron sinter

is used to produce pig iron on-site.

·

1.20 mmt of pig iron associated with unit

process emissions ( of 2.00 mmt CO2e. Of this

production, 0.60 mmt (50 percent) is used on-site to produce other products.

The facility reports that all of the pig iron that it uses is used in BOF

steelmaking.

·

0.80 mmt of carbon and alloy semifinished steel

in BOF steelmaking associated with unit process emissions ( ) of 0.40 mmt CO2e.

·

The facility does not report production of any

other products.

First, is calculated. No upstream materials made at

this facility are included in the calculation of this product-level emissions

inventory. Therefore, is equal to ,

or 0.40 mmt CO2e. Of those emissions, 0.20 mmt CO2e

(corresponding with the share of production used on-site) are allocated to

downstream products that use metallurgical coke. Based on the use of

metallurgical coke in the facility, is equal to 0.04 mmt CO2e

(corresponding with 20 percent of metallurgical coke use), and is equal to 0.16 mmt CO2e

(corresponding with 80 percent of metallurgical coke use).

Second, is calculated as the sum of and .

This sum is 0.34 mmt CO2e. All sinter is used on-site in the

production of pig iron. Therefore, is also 0.34 mmt CO2e.

Third, is calculated as the sum of ,

,

and .

This sum is 2.50 mmt CO2e. Of those emissions, 1.25 mmt CO2e

(corresponding with the share of production used on-site) are allocated to the

only downstream product made at the facility that uses pig iron, which is

semifinished steel. Therefore, is also equal to 1.25 mmt CO2e.

Fourth, is calculated as the sum of and ,

which is 2.50 mmt CO2e.

In all four summations of described above, other derivatives of are also included based on the material and product

relationships shown in table E.11. Because this facility has no material

production or product use of that material, all those derivatives are equal to

zero and are not depicted in the figure.

Figure

E.4 Example of how material flow analysis is used to calculate

product-level emissions inventories in an integrated steel facility

mcoke = metallurgical coke; sinter = iron sinter; pig =

pig iron; semi = carbon and alloy semifinished steel; UGHGproduct =

unit process emissions from production of the reference product; GHGproduct

= the product-level emissions inventory of the reference product; ICGHGmaterial,product

= emissions associated with upstream materials made in the same facility and

used in the production of the reference product; mmt CO2e = million

metric tons of carbon dioxide equivalent.

Source: Compiled by the USITC.

III.B. Material Flow Analysis for the Aluminum System

Boundary

In the United States, upstream materials used in the

production of aluminum products are not typically produced in the same facility

producing the aluminum productswith two

exceptions. First, carbon anodes are typically produced in the same facility as

primary unwrought aluminum. Incorporating emissions from the production of

carbon anodes (i.e., anode baking) into the primary unwrought aluminum

emissions estimate is straightforward as anode baking only maps to one productprimary

unwrought aluminum. Thus, all upstream emissions from anode baking material ( ) that is consumed on-site can be allocated to

primary unwrought aluminum ( ) and included in .

Second, secondary unwrought aluminum may be produced in the same facility as

wrought aluminum products and other noncovered products. Therefore, upstream

emissions from this on-site secondary unwrought aluminum production ( ) are included in the emissions inventories ( ) for all downstream wrought aluminum products

(e.g., aluminum bars, rods, and profiles) that use secondary unwrought aluminum

produced on-site.

III.C. Additional Analysis for Aggregate Product

Categories and Product Subcategories

The calculations in the sections above generate

product-level emissions inventories for reference products that correspond

directly with most product categories for which estimates are presented in this

report.569F

This section describes how the Commission calculated product-level emissions

inventories for products that are either aggregates or subcategories of

reference products.

III.C.1. Calculation of Product-Level Emissions Inventories for Product

Subcategories

The Commission calculated emissions intensity estimates for

certain steel products that are subcategories of reference products (see table

E.12 for a list of these products). For each subcategory ( ), the Commission calculated the product-level

emissions inventory ( ) using equation E.62.

|

|

|

|

Table E.12 List of reference

products with associated subcategories

|

Reference product(s)

|

Associated subcategories

|

|

Semifinished steel

|

Ingots and steel in other primary forms (carbon and

alloy, stainless); slabs (carbon and alloy, stainless); and all other forms

of semifinished steel (carbon and alloy, stainless)

|

|

Carbon and alloy hot-rolled flat

steel

|

Hot-rolled plate; all other

hot-rolled flat steel products

|

|

Carbon and alloy hot-worked long steel

|

Rebar; wire rod; heavy structural shapes and sheet

piling; all other hot-worked long steel products

|

|

Cold-formed long steel

|

Wire (carbon and alloy,

stainless); all other forms of cold-formed long steel products (carbon and

alloy, stainless)

|

|

Carbon and alloy seamless steel tubular products

|

Seamless oil country tubular goods; all other

seamless steel tubular products

|

|

Carbon and alloy non-seamless

steel tubular products

|

Non-seamless oil country tubular

goods; all other non-seamless steel tubular products

|

Source: Compiled by the USITC.

Note: The term “carbon and alloy,

stainless” indicates that both stainless steel and carbon and alloy steel types

of that reference product have associated subcategories of the same type.

This approach meant that, for a given facility, there was no

difference in the emissions intensities of the broader reference product and

underlying subcategories of products. Emissions intensity estimates presented

for different product subcategories do not reflect distinctions in production

practices within individual facilities that may affect the emissions

intensities of subcategories. For example, a facility that produces both rebar

and steel wire rod would not have a different emissions intensity for those

product subcategories, nor would those emissions intensities be distinct from

carbon and alloy hot-worked long products generally. However, for the

industry-wide estimates presented in this report, the different production

practices and efficiencies of facilities and the different concentration of

product subcategories across all facilities is reflected in distinct estimates

for each subcategory. Using the above example again, the industry-wide

emissions intensity for rebar and wire rod will differ from each other based on

the hot-worked long product emissions intensities of the facilities

concentrated in either product subcategory.

III.C.2. Calculation of Product-Level Emissions Inventories for Aggregate

Product Categories

Certain product categories are aggregates of other product

categories and therefore encompass multiple underlying reference products (see

table E.13). Aggregate product categories are steel product categories

specified in the Trade Representative’s letter under attachment A.570F

Table E.13 List of aggregate product

categories and underlying reference products

|

Aggregate product categories

|

Underlying reference products

|

|

Unwrought aluminum

|

Primary unwrought aluminum; secondary unwrought

aluminum

|

|

Wrought aluminum

|

Bars, rods, and profiles; wire;

plates, sheets, and strip; foil; tubes, pipes, and tube or pipe fittings;

castings; forgings

|

|

Carbon and alloy flat steel

|

Carbon and alloy hot-rolled flat steel; carbon and

alloy cold-rolled flat steel; carbon and alloy coated flat steel

|

|

Carbon and alloy long steel

|

Carbon and alloy hot-worked long

steel; carbon and alloy cold-formed long steel

|

|

Carbon and alloy tubular steel

|

Seamless steel tubular products; non-seamless steel

tubular products

|

|

Stainless steel

|

Stainless semifinished steel;

stainless hot-rolled flat steel; stainless cold-rolled flat steel; stainless

hot-worked long steel; stainless cold-formed long steel; stainless seamless

tubular steel products; stainless non-seamless tubular steel products

|

Source: Compiled by the USITC.

The emissions inventories of unwrought aluminum, wrought

aluminum, and carbon and alloy tubular steel are the sums of the product-level

emissions inventories of underlying reference products. For stainless steel

products ( ), carbon and alloy flat steel products ( ), and carbon and alloy long steel products ( ), the underlying reference products were

vertically integrated. As a result, product-level emissions inventories for

downstream underlying reference products (e.g., carbon and alloy cold-rolled

flat steel products) included emissions associated with the production of

upstream underlying reference products (e.g., carbon and alloy hot-rolled flat

steel products). The Commission calculated the emissions inventories of each of

these three aggregate product categories by summing for all underlying reference products and by

subtracting all terms for where both and referred to underlying reference products.571F